Company dynamics

Preparation and Documentation Required Prior to Mold Shipping

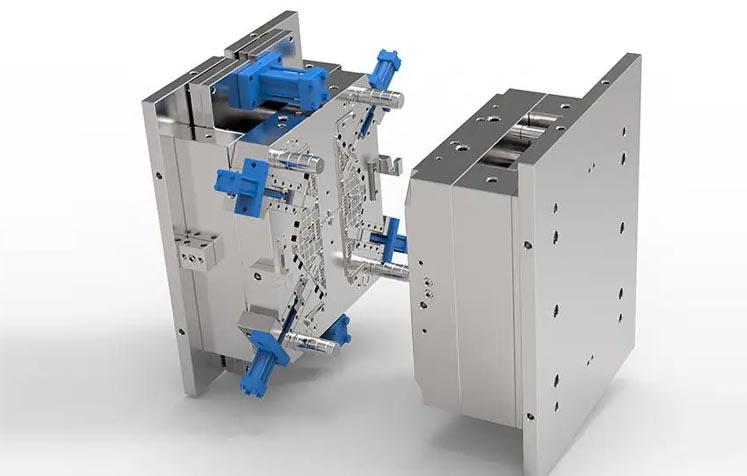

As a Medical linjection molding product manufacture, it is our prime responsibility to ensure that the molds meet the customer's requirements and achieve the highest standard of quality. To fulfill this objective, we must adhere to the following checking procedure, ensuring all necessary documents are packed in the shipping box before the mold is dispatched:

1. Preparation for Shipment : Make sure all required documents are packed in the shipping box before dispatching the mold.

2. 2D Mold Assembly Drawing : Provide a hard copy of the 2D mold assembly drawing for the customer to understand the structure and assembly of the mold.

3. 2D Part Drawing : Attach a hard copy of the 2D part drawing to confirm the specifications and design of the parts.

4. Drawing Documentation : Provide electronic copies of all 2D and 3D part drawings (burned onto a CD) to ensure the customer has comprehensive details of the mold.

5. Hot Runner Drawing : If applicable, provide the hot runner drawing to understand the working principle and layout.

6. Sample Photos and Video : Attach quick photos of the samples and a two-cycle auto-injection video (burned onto a CD) to demonstrate the actual working effect of the mold.

7. Mold Electrodes : Include all mold electrodes for potential modifications or maintenance by the customer.

8. Short Sample : Provide a short sample from the final trial for the customer to conduct final testing and verification.

9. Injection Molding Parameter Copy : Provide a copy of the injection molding parameters for the customer to understand and adjust the production process.

10. Steel Certificate for Core and Cavity : Provide a steel certificate for the core and cavity to attest to the quality and source of the material.

11. Dimension Measurement Report : Attach a dimension measurement report for the last samples to ensure the dimensions meet the design requirements.

12. Hardness Treatment Certificate for Core and Cavity Steel : Provide a hardness treatment certificate for the core and cavity steel to confirm the appropriate heat treatment process.

13. Measurement Report for Mold Steels : Provide a measurement report for the mold steels, detailing the physical properties such as hardness and dimensional accuracy.

By following these checking procedures, we can ensure the completeness and quality of the mold, meet the customer's expectations, and provide efficient and reliable production support.

Categories

Blog

Contact Us

Contact: plastic injection molding Company

Phone: +86 181 6575 9852

Tel: +86 755-27164277

E-mail: windward@seaiint.com

Add: Northwest of Huihao Industrial Park, No. 1, Chuangwei Road, Guangming District, Shenzhen