Company dynamics

How to design the unloading device and limit device in the stamping progressive die

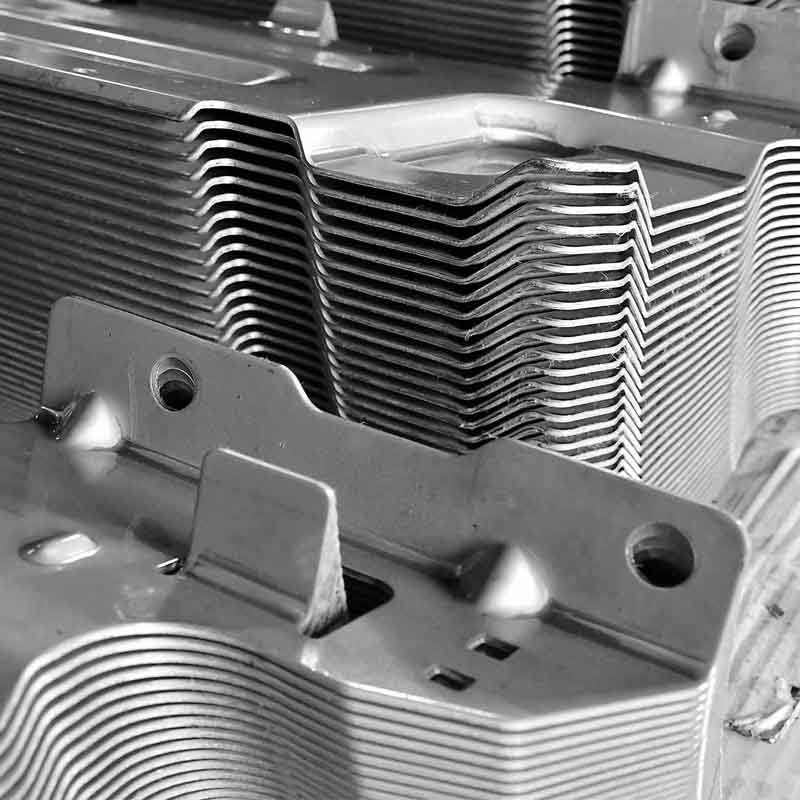

Oven stamping products unloading device is an important component in the multi-station precision progressive die structure. Its function is not only to press the strip material before the start of stamping to prevent the strip material from moving due to the different order or uneven force of each punch during stamping, and to ensure timely and smooth unloading after the stamping is completed, but more importantly, it plays a precise guiding and effective protection role for the punches (especially small punches) on each station when subjected to the measured force. The unloading device is mainly composed of a unloading plate, an elastic element, an unloading screw and auxiliary guiding parts.

1. Structure of the stripper plate

The spring-loaded stripper plate of the multi-station precision progressive die has many holes and complex shapes. In order to ensure the dimensional accuracy, position accuracy and matching clearance of the holes, it is often fixed on a base with greater rigidity by a segmented assembly structure. The base is slotted according to the matching relationship of the base hole system. The two pieces at both ends are pressed into the base slot according to the position accuracy requirements, and then fixed with screws and pins respectively. The three middle pieces are directly pressed into the slot after grinding and connected to the base only with screws. The installation position size is adjusted by grinding the joint surface of each segment, so as to control the dimensional accuracy and position accuracy of each hole.

2. Guide form of the stripper plate

Since the stripper plate has the function of protecting the small punch, the stripper plate is required to have high movement accuracy. For this reason, auxiliary guide parts, a small guide column and a small guide sleeve, should be added between the stripper plate and the upper die seat. When the stamping material is relatively thin, the mold has high accuracy requirements, and the number of stations is large, ball guide columns and guide sleeves should be used.

3. Installation form of the stripper plate

The stripper plate is hoisted on the upper die by stripper screws. The stripper screws should be symmetrically distributed and the working length should be strictly consistent. The precision of the shaft length L of the external thread type is +0.1mm, which is often used in ordinary progressive dies with few stations: the shaft length precision of the internal thread type is ±0.02mm, and the working length of a group of stripper screws can be kept consistent by grinding the shaft end face; the combined type is composed of a sleeve, a bolt and a washer, and its shaft length precision can be controlled within ±0.01mm. There is another very important feature of the internal thread and the combined type. When the punching punch is sharpened after a certain number of times, the length of the working section of the stripper screw must be ground off by the same amount to ensure the relative position of the pressing surface of the stripper plate and the end face of the punching punch. The grinding of the working section of the external threaded stripper screw is more difficult.

The installation form of the stripper plate is a commonly used structure in multi-station precision progressive dies. The pressing force and unloading force of the stripper plate are provided by the uniformly distributed springs installed on the stripper plate (preferably a rectangular cross-section spring). Since the clearance between the stripper plate and each punch is only 0.005mm, it is troublesome to install the stripper plate. Try not to remove the stripper plate from the punch unless it is absolutely necessary. Considering that it is not necessary to remove the stripper plate from the punch during sharpening, and the stripper plate must be lower than the end face of the punch cutting edge, the spring is fixed in the upper die and limited by a screw plug. When sharpening, just unscrew the screw plug, the spring can be taken out, and the stripper plate that is not affected by the spring can be moved to expose the end face of the punch cutting edge, so that the cutting edge can be re-sharpened. At the same time, it is also very convenient to replace the spring. If the stripper screw adopts a sleeve combination type, the size of the grinding sleeve can adjust the position of the stripper plate relative to the punch, and the grinding gasket can adjust the stripper plate to achieve the ideal dynamic parallelism (relative to the upper and lower dies) requirements. When punching the head and tail of the material, in order to make the stripper plate move smoothly and the pressing force balanced, a balance pin should be installed at the appropriate position of the stripper plate to balance the movement of the stripper plate.

Limiting device

The structure of the progressive die is complex and there are many punches. During storage, transportation and die trial, the punches enter the die too much, which is easy to damage the die. Therefore, when designing the progressive die, the installation of a limiting device should be considered. The limiting device consists of a limiting column, a limiting pad and a limiting sleeve. When installing the die on the punch press, the limiting pad is installed, and the die is in a closed state. Fix the die on the punch press, remove the limiting pad, and the die can work, which is very convenient for installing the die. Before removing the die from the punch press, put the limiting sleeve on the limiting column, and the die is in an open state, which is convenient for transportation and storage.

When the precision requirements of the Oven stamping products die are high and the die has more small punches, a limiting pad can be designed between the spring-pressed stripper plate and the punch fixing plate, which can play a more accurate limiting role in controlling the punch stroke.

PREVIOUS:custom plastic products manufacturers NEXT:Period

Categories

Blog

Contact Us

Contact: plastic injection molding Company

Phone: +86 181 6575 9852

Tel: +86 755-27164277

E-mail: windward@seaiint.com

Add: Northwest of Huihao Industrial Park, No. 1, Chuangwei Road, Guangming District, Shenzhen