Company dynamics

Plastic injection mold processing manufacturer

Customers want to produce plastic products, then plastic injection molding manufacturers, the first step is to create an injection mold. The mold is the key to defining the shape of the product.

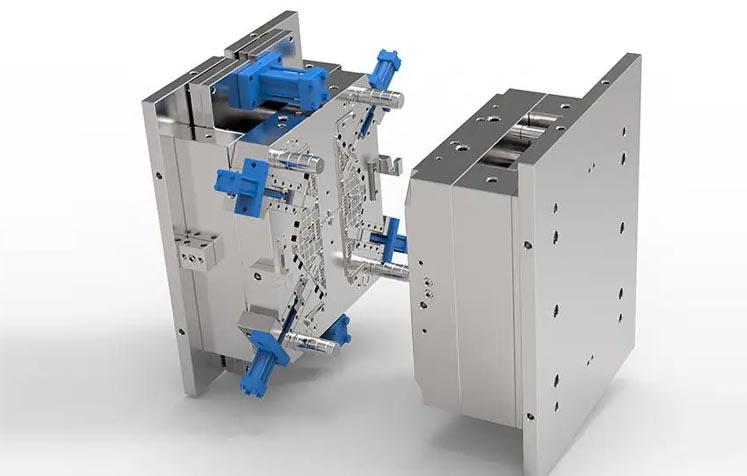

The injection molding process relies on molds, usually made of steel or aluminum, used as custom tools. The mold usually consists of multiple parts, but can be simplified to two main halves. These halves are installed inside the injection molding machine, and the back half can slide so that the mold can be opened and closed along its parting line. The two main parts of the mold are the core and the cavity. When the mold is closed, the space between these parts forms the part cavity, and the molten plastic is injected into it to form the desired shape. In some cases, multi-cavity molds are used to create multiple identical parts at the same time.

The core and cavity are connected to the mold base separately, and then the mold base is fixed to the pressure plate inside the injection molding machine. The front half of the mold base includes a support plate for the mold cavity, a sprue bushing to direct the material out of the nozzle, and a locating ring to align the mold base with the nozzle. The back half includes an ejector system connected to the mold core and another support plate. When the machine's clamping unit separates the mold halves, an ejector pin activates the ejector system. The ejector pin pushes the ejector plate forward inside the ejector box, allowing the ejector pin to push the molded part out of the open cavity.

The life of the mold depends on the steel used for the inserts. Molds made with pre-hardened steel typically last about 300,000 injections. However, molds with inserts made of hardened steel (such as grade 1.2344) can withstand up to 1,000,000 injections. The cost of mold tooling varies widely due to the expensive material (steel), the complex manufacturing process, and the need for skilled professionals. Prices typically range from $1,000 to $300,000.

Categories

Blog

Contact Us

Contact: plastic injection molding Company

Phone: +86 181 6575 9852

Tel: +86 755-27164277

E-mail: windward@seaiint.com

Add: Northwest of Huihao Industrial Park, No. 1, Chuangwei Road, Guangming District, Shenzhen