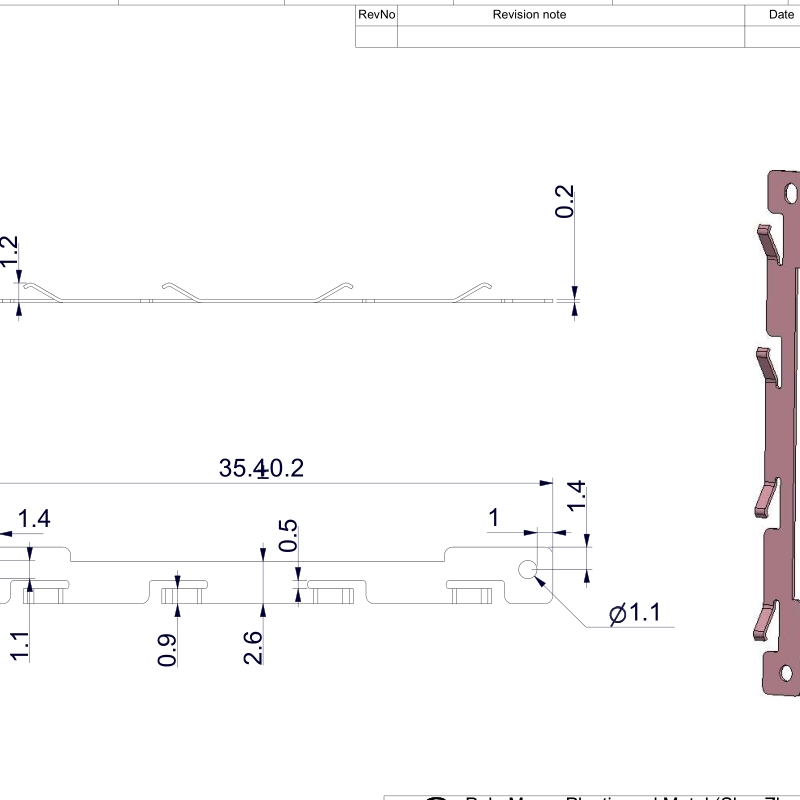

metal stamping Parts

Socket spring stamping products

Socket spring stamping products stainless steel stampings suppliers

One-stop service

With the rapid development of electronic technology, socket spring stamping products are indispensable components in electronic equipment, and their performance and quality are crucial to the stability and reliability of the entire equipment. Some shrapnels are made of copper to ensure electrical conductivity, and some are made of stainless steel, but no matter which material is used, it should be based on customer needs.

1. High-end products: excellent quality and performance

In the field of socket spring stamping products, we are committed to providing high-end quality products. We use advanced production processes and materials to propose solutions according to customer needs to ensure product stability and reliability. At the same time, we continue to optimize product structure and design to improve product performance and life. Our high-end products not only have excellent shrapnel insertion and extraction performance, but also have excellent mechanical properties and environmental resistance, which can meet the needs of use in various complex environments.

2. Structural engineering and design: innovation leads development

In terms of structural engineering and design of socket spring stamping products, we focus on innovation and optimization. We have a professional R&D team that constantly researches and explores new structural design solutions. We use advanced simulation analysis technology and experimental verification methods to ensure that the structural design and performance of our products meet customer needs.

3. Enhanced functions: meet diverse needs

In order to meet the needs of different customers, we continue to develop and enhance the functions of socket spring stamping products. We pay attention to the safety, stability and reliability of our products, and have added safety protection functions such as anti-misplugging, anti-overloading, and anti-lightning strikes. At the same time, we also focus on product intelligence and automation, and have developed smart socket shrapnel products with intelligent identification, remote control and other functions. These enhanced functions not only improve the added value and competitiveness of the product, but also bring a more convenient and efficient usage experience to customers.

4. One-stop service for mold opening, injection molding and metal stamping: create a comprehensive solution

In order to meet customers' comprehensive needs for socket spring stamping products, we provide one-stop services of mold opening, injection molding and metal stamping. We have advanced production equipment and technical teams, able to provide customers with full-process services from product design, mold development, manufacturing to quality inspection. This one-stop service model not only improves production efficiency and quality stability, but also reduces customers' costs and time investment. We will continue to improve and optimize this service model to provide customers with more comprehensive and professional solutions.

6. Real brand influence: setting industry benchmarks

In the fiercely competitive socket spring stamping product market, brand influence is one of the key factors for a company's success. We focus on brand building and maintenance, and constantly improve product quality and service levels. We actively participate in industry exchanges and cooperation, promote new technologies and applications, and set industry benchmarks and models. Our brand not only represents excellent quality and professional service, but also represents our commitment and trust to our customers. We will continue to adhere to the business philosophy of "quality first, customer first" to provide customers with better products and services.

7. Sustainable cooperation: creating a better future together

We value our cooperative relationships with our customers and are committed to establishing long-term and stable partnerships with our customers. We will provide customers with all-round support and services with a professional technical team, excellent service quality and efficient production capacity. We will pay close attention to changes in the market and technology, continue to innovate and optimize products, and meet the changing needs of customers. We look forward to working together with our customers to create a better future.

8. Free quotation: tailor-made solutions

To help customers better understand our products and services, we provide free quotation services. Customers only need to provide specific requirements and specifications, and our professional team will provide customers with customized quotations and solutions. We will create value for our customers with our sincere attitude and professional services, and win their trust and satisfaction.

9. Conclusion

Socket spring metal stamping products are an important part of electronic connectors, and their quality and technical content are crucial to the performance and stability of the entire electronic device. We will keep up with industry trends and market demands, and continue to innovate and optimize products. We will win the trust and satisfaction of our customers with high-quality products, professional services and excellent brand influence. We look forward to establishing long-term and stable partnerships with our customers to create a better future.

PREVIOUS:copper stamping NEXT:Antenna fixed sheet stamping products

Categories

Blog

Contact Us

Contact: plastic injection molding Company

Phone: +86 181 6575 9852

Tel: +86 755-27164277

E-mail: windward@seaiint.com

Add: Northwest of Huihao Industrial Park, No. 1, Chuangwei Road, Guangming District, Shenzhen