Company dynamics

ABS plastic injection molding FAQs

ABS plastic injection molding suppliers FAQs

Flow: related to the speed of the injection molding machine, including screw speed, injection speed, mold support and neutron speed, etc.

Screw speed: In addition to adjusting the pre-plastic flow rate, it is mainly affected by the pre-plastic back pressure. If the pre-molding flow rate is adjusted to a large value and the pre-molding back pressure is high, as the screw rotates, the plastic will have a large shear force in the barrel, and the plastic molecular structure will be easily cut off. The product will have black spots and black stripes, which will affect the appearance quality and strength of the product. , and the barrel heating temperature is difficult to control. If the pre-plastic flow rate is set too low, the pre-plastic storage time will be extended, which will affect the molding cycle.

Injection speed: The injection speed must be set reasonably, otherwise it will affect product quality. If the injection speed is too fast, the product will have bubbles, burnt, discolored, etc. If the injection speed is too slow, the product will be insufficiently formed and have weld marks.

Support mold and neutron flow rate: should not be set too high, otherwise the ejection and core pulling movements will be too fast, resulting in unstable ejection and core pulling, and the product will easily turn white.

2. Time setting: In the injection molding process, there are drying time, injection and holding time, cooling time, etc.

Drying time: It is the drying time for plastic raw materials. Various types of plastics have optimal drying temperatures and times. The drying temperature of ABS plastic is 80~90℃ and the drying time is 2 hours. ABS plastic generally absorbs 0.2 to 0.4% water within 24 hours, and the water content that can be injection molded is 0.1 to 0.2%.

Injection and pressure holding time: The control method of the computer injection machine is equipped with multi-stage injection to adjust the pressure, speed and injection plastic amount in stages. The speed of plastic injected into the mold cavity reaches a constant speed, and the appearance and internal material quality of the molded products are improved.

Therefore, the injection process often uses position control instead of time control. The holding pressure is controlled by time. If the holding time is long, the product density will be high, the weight will be heavy, the internal stress will be large, demoulding will be difficult, it will be easy to whiten, and the molding cycle will be extended. If the holding time is too short, the product will be prone to dents and unstable dimensions.

Cooling time: It is to ensure that the product is stable in shape. It requires sufficient cooling and shaping time after the plastic injected into the mold cavity is molded into the product. Otherwise, the product is easy to warp and deform when the mold is opened, and the ejection is easy to deform and become white. The cooling time is too long, which prolongs the molding cycle and is uneconomical.

3. Position control: Some injection molding machines have mold transfer position, mold supporting position, material storage and injection position control.

The mold shifting position is the entire moving distance from mold opening to mold closing and locking, which is called the mold shifting position. The best position to move the mold is to be able to take out the product smoothly. If the mold opening distance is too large, the molding cycle will be long. As long as the position of the mold support is controlled, the position of ejection from the mold can be easily removed and the product can be removed.

Storage location: Firstly, the amount of plastic injected into the molded product must be ensured, and secondly, the amount of material stored in the barrel must be controlled. If the storage position is controlled by more than one shot, the product will easily flash, otherwise the product will be insufficiently formed. If there is too much material in the barrel, the plastic will stay in the barrel for a long time, and the product will easily fade and affect the strength of the molded product. On the contrary, it affects the quality of plastic plasticization, and no material is replenished into the mold during pressure maintaining, resulting in insufficient molding of the product and dents.

Summarize

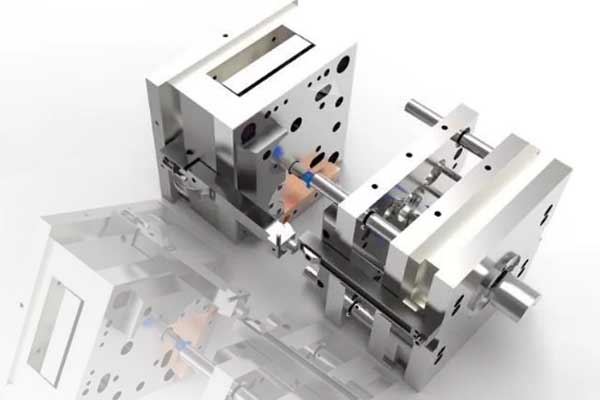

The quality of injection molded products involves product design, plastic materials, mold design and processing quality, injection molding machine selection and process adjustment, etc.

For normal production of molds, the only way to ensure and improve product quality is to adjust the injection process; that is, adjust the temperature, pressure, flow rate, time and position.

Process adjustments must be comprehensive and coordinated. If the size of the product changes greatly, you can start to consider the plastic raw materials, whether it is crystalline plastic or amorphous plastic, the size of the plastic molecular weight, etc. It is a crystalline plastic and a macromolecular plastic. It is necessary to consider the crystallinity and molecular orientation of the product. The shape of the product will change the flow during molding, which will cause changes in the internal stress and size of the product, causing shrinkage changes in the product.

To solve the problem of small changes in the size of the product, we can increase the material temperature, lower the mold temperature, control the amount of injection material, reduce the injection pressure, increase the injection speed, fill the mold cavity instantly, reduce the holding pressure time, and extend the cooling time. Reduce the density of the product while ensuring that the product is fully shot. To reduce the internal stress of the product and reduce the shrinkage change of the product.

In short, the adjustment of the injection process cannot only start from a certain point, but must start from the principle of the injection process. Comprehensive and comprehensive consideration of issues, adjustments can be made one by one from multiple aspects or multiple issues can be adjusted at once. However, the adjustment method and principle depend on the quality and process conditions of the products produced at that time.

Categories

Blog

Contact Us

Contact: plastic injection molding Company

Phone: +86 181 6575 9852

Tel: +86 755-27164277

E-mail: windward@seaiint.com

Add: Northwest of Huihao Industrial Park, No. 1, Chuangwei Road, Guangming District, Shenzhen